- Home

-

Products

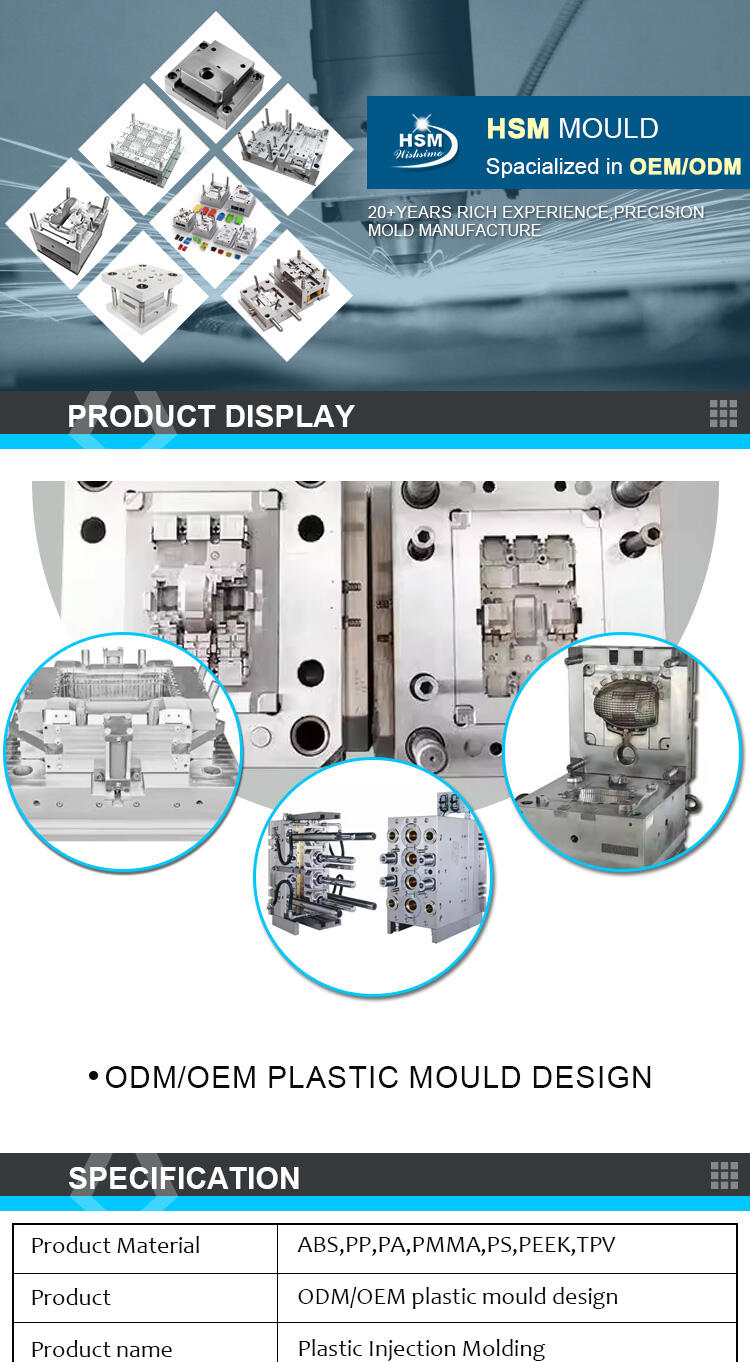

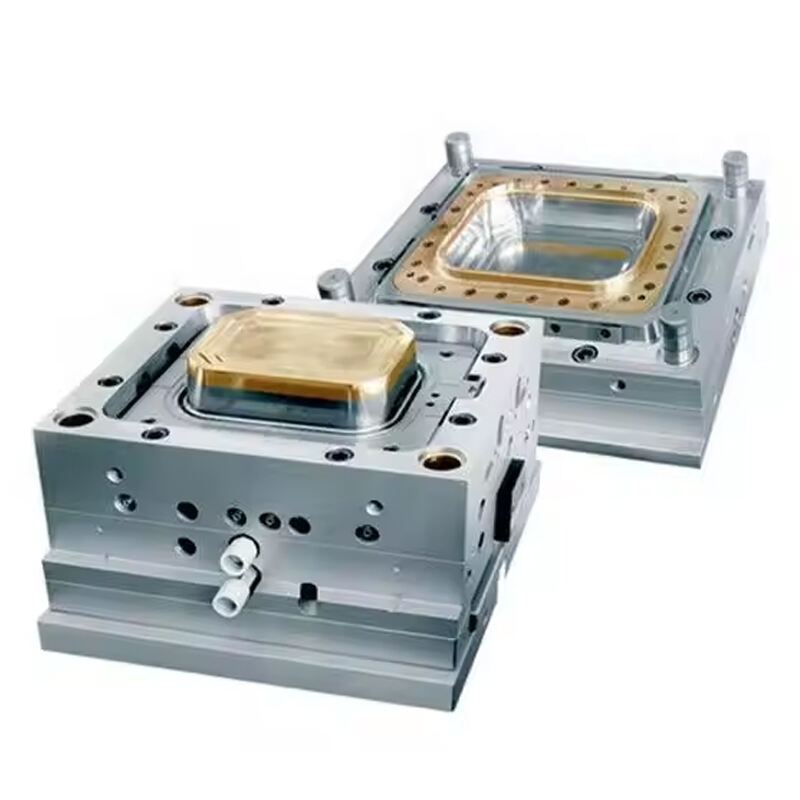

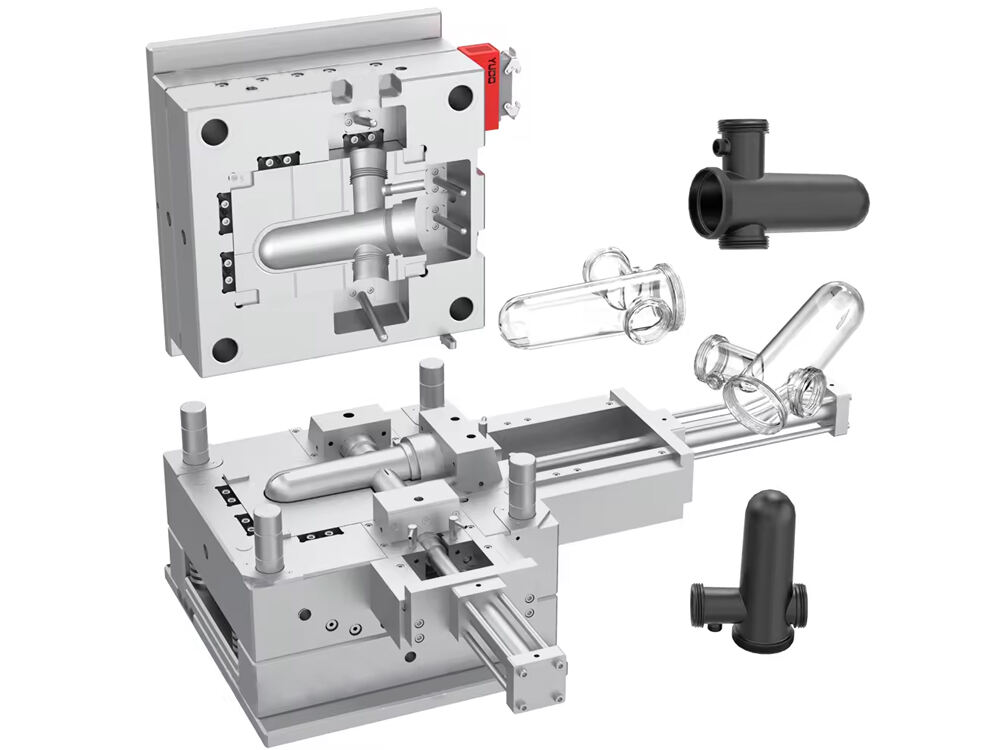

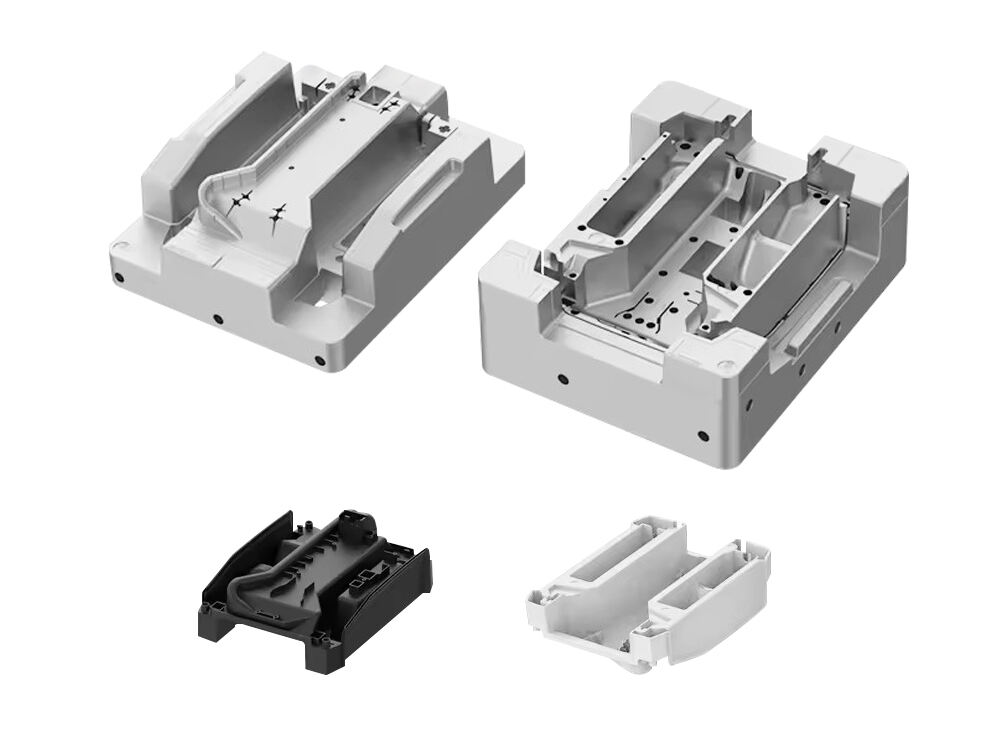

- ODM/OEM plastic mould design

- Plastic Mold Components

- Overmolding Injection Molding

- Gear Mold

- Home Appliance Mould

- Unscrewing Mold

- High Temperature Plastic Mold

- Electronics Injection Molding

- Multi Cavity Injection Molding

- Medical Injection Molding

- Double Shot Injection Molding

- Automotive Injection Mold

- Plastic Auto Parts Mould

- Car Parts Mold

- Injection Mould

- About Us

- Service

- News

- Case

- Contact Us

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ

Hot News

Hot News