Jan 16, 2026

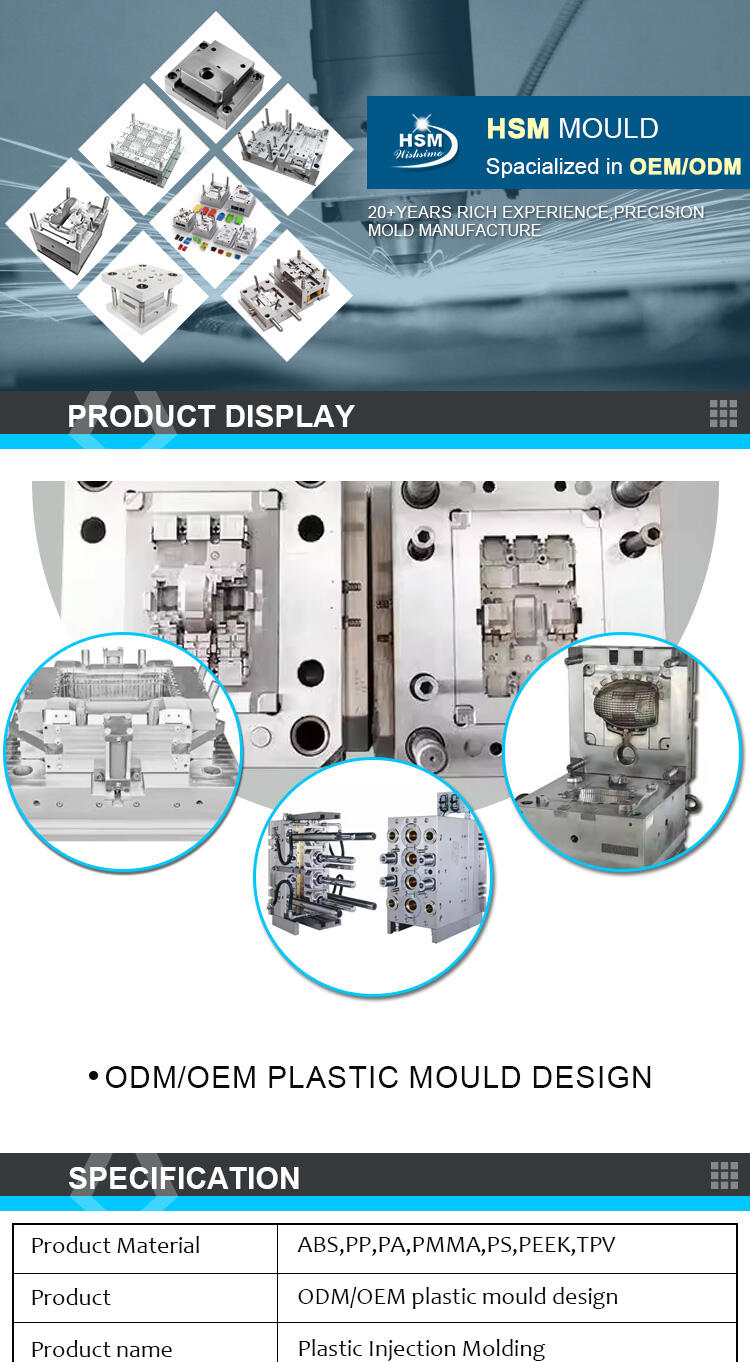

ပစ္စည်းများ ပုံပျက်ခြင်း၊ အပေါ်ယံတွင် ပလပ်စတစ်များ ထွက်လာခြင်း (flash) သို့မဟုတ် အကုန်စုံမှုနှုန်း ၁၅% အထိ ဖြစ်ပွားခြင်းတို့ဖြင့် ပြဿနာရှိနေပါသလား။ ကျွန်ုပ်တို့၏ အဆင့်သုံးဆင့်ပါသော အရည်အသွေးထိန်းချုပ်မှု ကွက်ကွက်ကွက် (3-tier QC framework) — မော်လ်မှုန်းမှုမှုန်းမှု အတည်ပြုခြင်း (pre-mold validation)၊ အချိန်နှင့်တစ်ပါတည်း SPC စောင်းစောင်းစောင်း (real-time SPC) နှင့် အမြစ်အကြောင်းရင်း ဆန်းစစ်ခြင်း (root-cause analysis) — သည် အကွက်များကို ၂၂% အထိ လျော့ချပေးပါသည်။ ထို့အပ alongside ±0.02mm အတိအကျမှုကို အာမခံပေးပါသည်။ အခမဲ့ အရည်အသွေးထိန်းချုပ်မှု အကဲဖြတ်မှုကို ရယူပါ။

ပိုမိုဖတ်ရန်

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ

အပူပြင်းသော သတင်း

အပူပြင်းသော သတင်း