တြက္ခ်င္းမူရင္း

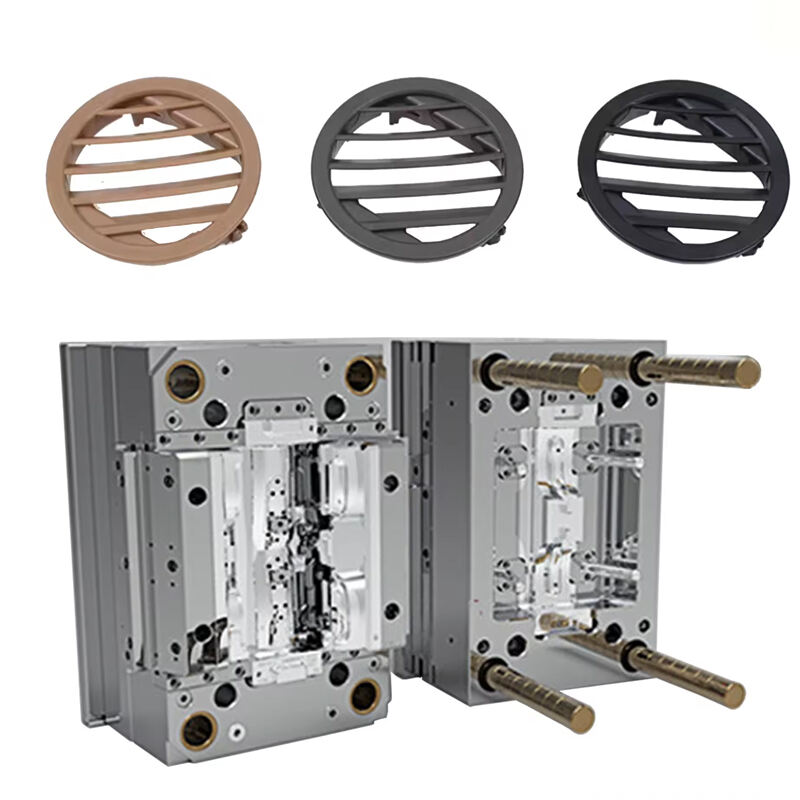

အတိအကျရှိသော ဖြည့်သွင်းမှုနည်းလမ်းဖြစ်သည့် Injection molding သည် အိမ်သုံးပစ္စည်းများကို အထိရောက်ဆုံးထိန်းချုပ်နိုင်သော smart home စက်မှုလုပ်ငန်းကို တော်လှန်ပြောင်းလဲခဲ့ပါသည်။ ၎င်းသည် စက်တပ်ဆင်ထားသော ကိရိယာများ၊ အဆင့်မြင့်ပစ္စည်းများ၊ အစိတ်အပိုင်းများ စသည့် smart home ကိရိယာများအတွက် ရှုပ်ထွေးပြီး ခိုင်ခံ့သော အစိတ်အပိုင်းများကို ထုတ်လုပ်ရာတွင် အထောက်အကူပြုပါသည်။ မော်လ်ဒ်ထုတ်လုပ်မှုတွင် ကျွန်ုပ်တို့၏ ကျွမ်းကျင်မှုနှင့် အတွေ့အကြုံ ၂၀ နှစ်ရှိခြင်းတို့က အရည်အသွေးမြင့်၊ တိကျပြီး စျေးနှုန်းချိုသာသော ထုတ်လုပ်မှုကို သေချာစေပါသည်။ ကျွန်ုပ်တို့သည် ဒီဇိုင်းမှ ပရိုတိုတိုင်းထုတ်လုပ်ခြင်း၊ ထုတ်လုပ်မှုနှင့် တပ်ဆင်ခြင်းအထိ ဝန်ဆောင်မှုတစ်ခုတည်းကို ပေးဆောင်ပြီး smart home ဈေးကွက်၏ ထူးခြားသော လိုအပ်ချက်များကို ဖြည့်ဆည်းပေးပါသည်။ ကျွန်ုပ်တို့၏ ခေတ်မီနည်းပညာများနှင့် အရည်အသွေးအပေါ် မပြောင်းလဲသော ကတိကဝတ်များဖြင့် smart home စက်မှုလုပ်ငန်းတွင် တီထွင်မှုများကို ဦးဆောင်ရန် ကျွန်ုပ်တို့ ကတိပြုထားပြီး ကျွန်ုပ်တို့၏ ဖောက်သည်များအတွက် ဘဝကို ပိုမိုလွယ်ကူစွာ၊ ပိုမိုလုံခြုံစွာနှင့် ပိုမိုသက်တောင့်သက်သာရှိစေရန် ကူညီပေးပါသည်

ဈေးကုတ်ယူရန်

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ