ຄວາມຖັກຕ້ອງແມ່ນຢູ່ໃຈຫຼັງຂອງການຜະລິດແມັດສຸ່ມຂອງ HSM ການປະເພດທີ່ສູງຂອງອຸປະກອນຂອງພວກເຮົາຊ່ອຍໃຫ້ຄວາມຖັກຕ້ອງຂອງມີຕິໂດເປັນຫນຶ່ງທີ່ບໍລິສັດ B2B ຄົ້ນຫາຄູນພະນັນແລະຄວາມສາມາດໃນການເຮັດວຽກຂະໜາດໃຫຍ່.

ທີ່ HSM, ພວກເຮົາຊຸມຊົມໃນການຜະລິດມາດລູ່ແປ້ຽນທີ່ມີຄວາມໜ້າຊັດສູງສຳລັບຄວາມຕ້ອງການຂອງການຜະລິດອຸຕະຫຼູ່. ຕົວແທນທີ່ມີຄວາມສຳເລັດຂອງພວກເຮົາແນະນຳວ່າ ມາດລູ່ແປ້ຽນທຸກຢ່າງສາມາດສົ່ງສິນຄ້າທີ່ມີຄວາມຖືກຕ້ອງໃນຄວາມຍາວແລະຄວາມສຳເລັດຂອງພື້ນໜ້າ. ພວກເຮົາຮູ້ຈັກການວຽກງານກັບພ້ານທີ່ B2B ເພື່ອພັດທະນາມື້ມື້ທີ່ສຳເລັດທີ່ສັງຄັບກັບການຜະລິດຫຼາຍທີ່ມີຄວາມແຕກຕ່າງນ້ອຍ. ມາດລູ່ HSM ທີ່ໜ້າຊັດແລະການສຶກສາທີ່ໜ້າສົງໃຫ້ມາດລູ່ທີ່ໜ້ອງໄວ້, ສູ້ຍາວ, ແລະເພີ່ມຄວາມສຳເລັດແລະຄວາມສຳເລັດ.

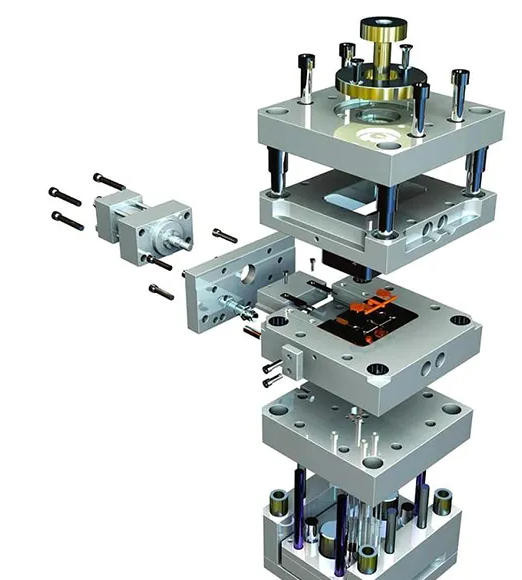

ຈາກຄຳຄິດເລີ່ມຕົ້ນເຖິງການສົ່ງສຳເລັດ, HSM ສະເຫຼີມການເຮັດວຽກທັງໝົດຂອງທ່ານໃນການແຮງຂູ່ຈຸລະນົມ. ກຸ່ມວຽກງານຂອງພວກເຮົາແນະນຳວ່າທຸກໆແຮງຂູ່ຖືກສ້າງຂຶ້ນໂດຍຄວາມປະຈຸບັນ, ເພື່ອໃຫ້ມີການປະສົມປະສານທີ່ສະຫວັດເຂົ້າກັບເສັ້ນຜົນิต B2B. ກັບການສະຫວັດອອກແບບແລະການກວດສອບຄຸນສຳພາດທີ່เขັມແຂງ, HSM ອັງຄຸມຜູ້ຜົນิตໃຫ້ສາມາດກັບຄວາມປະຕິບັດແລະສະເຫຼີມຄວາມຄົບຄຸ້ມຂອງລູກຄ້າ.

HSM ໄດ້ສ້າງຊື່ສຽງທີ່ເຂົ້າກັນໃນອຸຕະຫຼູ່ການແປ້ຽນແມ່ນໂຍມໂດຍການສົ່ງສິນຄ້າທີ່ໜ້ອງໄວ້ໄດ້. ມາດລູ່ແປ້ຽນຂອງພວກເຮົາຖືກອີງວິທີ້ດ້ວຍຄວາມສຳເລັດໃນຈິດ, ກັບໄວ້ການລົດລົ້ນຂອງສິນຄ້າແລະຄວາມສຳເລັດຂອງສິນຄ້າ. ກັບ R&D ໃນເຮືອນແລະຄວາມສາມາດໃນການຜະລິດທີ່ເຕັມໄປ, ພວກເຮົາສະຫນັບສະຫນູນມາດລູ່ແປ້ຽນທີ່ໜ້ອງໄວ້ໃຫ້ລູກຄ້າອຸຕະຫຼູ່ທົ່ວໂລກທີ່ຄົ້ນຫາຄຸນພາບທີ່ສາມາດເພີ່ມໄດ້.

ເມື່ອຄວາມສັກສຸນໃນການຂະຫຍາຍຕົວແມ່ນສຳຄັນ B2B ລູກຄ້າຈະເລືອກ HSM ເພື່ອແມ່ນບັດທີ່ສຳເລັດໄດ້ໃນຄວາມດູງ, ພວກເຮົາສົງສະຫິມຄວາມຖືກຕ້ອງແລະຄວາມສະຫຼຸບສະຫຼິມໃນການຜະລິດຫຼາຍ. ສົນຄ້າການແມ່ນບັດຂອງພວກເຮົາແມ່ນອົບເຕີມເພື່ອປຸດທີ່ສັ້ນກວ່າແລະປຸດສ່ວນທີ່ດີກວ່າ, ຢ່າງຊ່ວຍຜູ້ຜະລິດໃຫ້ສາມາດສົ່ງຄຳສັ່ງຕໍ່ຫາງຄ້າໂດຍບໍ່ສັນຍາຄຸນຄ່າ.

SuperTech Mold Limited, ກໍ່ຕັ້ງຂຶ້ນໃນປີ 2003, ດີເລີດໃນການສະຫນອງການແກ້ໄຂແບບຢຸດດຽວສໍາລັບການອອກແບບຜະລິດຕະພັນ, ການພັດທະນາ, ແລະການຜະລິດ. ດ້ວຍການສຸມໃສ່ຄຸນນະພາບແລະນະວັດກໍາ, ພວກເຮົາພະຍາຍາມເພື່ອຕອບສະຫນອງຄວາມຕ້ອງການຂອງລູກຄ້າຂອງພວກເຮົາ.

ແມ່ພິມເກຍສະຫນອງຄວາມແມ່ນຍໍາທີ່ບໍ່ສາມາດປຽບທຽບໄດ້, ຮັບປະກັນການຜະລິດເກຍທີ່ບໍ່ມີຮອຍຕໍ່ທີ່ມີຂໍ້ບົກພ່ອງຫນ້ອຍທີ່ສຸດ. ຂະບວນການອອກແບບແລະການຜະລິດແບບພິເສດຂອງມັນຮັບປະກັນຄວາມແນ່ນອນທີ່ຕ້ອງການສໍາລັບເກຍ, ເພີ່ມປະສິດທິພາບແລະການປະຕິບັດໃນການນໍາໃຊ້ຕ່າງໆ. ຈາກລົດຍົນໄປສູ່ຂະແຫນງອຸດສາຫະກໍາ, mold gear ຊ່ວຍໃຫ້ການຜະລິດເກຍທີ່ມີຄຸນນະພາບສູງທີ່ເຮັດວຽກໄດ້ອຍ່າງລຽບງ່າຍແລະເຊື່ອຖືໄດ້, ຕອບສະຫນອງຄວາມຕ້ອງການຂອງສະພາບແວດລ້ອມທີ່ຕ້ອງການທີ່ສຸດ. ດ້ວຍໂຄງສ້າງແຂ້ວທີ່ຊັດເຈນແລະການກໍ່ສ້າງທີ່ທົນທານ, mold gear ອໍານວຍຄວາມສະດວກໃນການສ້າງເກຍທີ່ດີເລີດໃນການສົ່ງໄຟຟ້າ, ສະຫນອງການເຮັດວຽກທີ່ດີທີ່ສຸດແລະອາຍຸຍືນ.

ແມ່ພິມເຄື່ອງໃຊ້ໃນເຮືອນໃຫ້ການອອກແບບທີ່ເຫມາະສົມເພື່ອສ້າງເຄື່ອງໃຊ້ໃນເຮືອນພິເສດທີ່ຕອບສະຫນອງຄວາມຕ້ອງການຂອງຜູ້ບໍລິໂພກ. versatility ຂອງມັນອະນຸຍາດໃຫ້ການຜະລິດຂອງລະດັບຄວາມກ້ວາງຂອງເຄື່ອງໃຊ້, ຈາກຕູ້ເຢັນກັບເຄື່ອງຊັກຜ້າ, ມີຄວາມແມ່ນຍໍາແລະປະສິດທິພາບ. ດ້ວຍການອອກແບບແມ່ພິມທີ່ກໍາຫນົດເອງ, ຜູ້ຜະລິດສາມາດປະດິດສ້າງແລະຄວາມແຕກຕ່າງຂອງຜະລິດຕະພັນຂອງພວກເຂົາ, ສະເຫນີຄຸນນະສົມບັດທີ່ເພີ່ມຄວາມສະດວກ, ປະສິດທິພາບພະລັງງານ, ແລະຄວາມທົນທານ. mold ເຄື່ອງໃຊ້ໃນເຮືອນຮັບປະກັນຄຸນນະພາບທີ່ສອດຄ່ອງ, ເຮັດໃຫ້ການສ້າງເຄື່ອງໃຊ້ທີ່ຊ່ວຍເພີ່ມຊີວິດຂອງຜູ້ບໍລິໂພກແລະໂດດເດັ່ນໃນຕະຫຼາດທີ່ມີການແຂ່ງຂັນ.

ການສີດແມ່ພິມສະຫນອງການຜະລິດແບບຕົ້ນແບບຢ່າງໄວວາແລະຄ່າໃຊ້ຈ່າຍທີ່ມີປະສິດທິພາບສໍາລັບຜະລິດຕະພັນທີ່ຫລາກຫລາຍ. ຄວາມສາມາດໃນການສ້າງຮູບຮ່າງທີ່ຊັບຊ້ອນທີ່ມີຄວາມແມ່ນຍໍາສູງແລະເຮັດຊ້ໍາໄດ້ເຮັດໃຫ້ມັນເຫມາະສົມສໍາລັບການຜະລິດຂະຫນາດໃຫຍ່ຂອງອົງປະກອບສໍາລັບອຸດສາຫະກໍາຕ່າງໆ. ດ້ວຍເວລາການນໍາສັ້ນແລະຄ່າໃຊ້ຈ່າຍຕໍ່ຫນ່ວຍຕ່ໍາ, ການສີດແມ່ພິມເຮັດໃຫ້ຜູ້ຜະລິດສາມາດນໍາເອົາຜະລິດຕະພັນອອກສູ່ຕະຫຼາດໄດ້ໄວແລະລາຄາຖືກ. ຈາກສິນຄ້າອຸປະໂພກບໍລິໂພກໄປສູ່ຊິ້ນສ່ວນລົດຍົນ, ການສີດແມ່ພິມເຮັດໃຫ້ຂະບວນການຜະລິດ, ຫຼຸດຜ່ອນສິ່ງເສດເຫຼືອ, ແລະເພີ່ມປະສິດທິພາບໂດຍລວມ, ເຮັດໃຫ້ມັນເປັນທາງເລືອກທີ່ມັກສໍາລັບຜູ້ຜະລິດທົ່ວໂລກ.

ແມ່ພິມສີດຮັບປະກັນຄຸນນະພາບດີກວ່າແລະຄວາມສອດຄ່ອງໃນການຜະລິດ, ຕອບສະຫນອງຄວາມຕ້ອງການທີ່ເຂັ້ມງວດຂອງອຸດສາຫະກໍາທີ່ທັນສະໄຫມ. ການອອກແບບແລະການກໍ່ສ້າງທີ່ຊັດເຈນຂອງມັນເຮັດໃຫ້ການຜະລິດຊິ້ນສ່ວນທີ່ສັບສົນດ້ວຍຄວາມທົນທານທີ່ແຫນ້ນຫນາ, ຮັບປະກັນການປະຕິບັດແລະການເຮັດວຽກທີ່ຫນ້າເຊື່ອຖື. ການກໍ່ສ້າງທີ່ເຂັ້ມແຂງຂອງແມ່ພິມສີດແລະວັດສະດຸກ້າວຫນ້າທາງດ້ານທົນທານຕໍ່ຄວາມເຄັ່ງຄັດຂອງການຜະລິດທີ່ມີປະລິມານສູງ, ໃຫ້ຜົນໄດ້ຮັບທີ່ສອດຄ່ອງໃນໄລຍະເວລາທີ່ຍາວນານ. ດ້ວຍຄວາມສາມາດໃນການສ້າງເລຂາຄະນິດທີ່ສັບສົນແລະລາຍລະອຽດທີ່ສັບສົນ, ແມ່ພິມສີດອໍານວຍຄວາມສະດວກໃນການຜະລິດອົງປະກອບທີ່ສອດຄ່ອງກັບມາດຕະຖານສູງສຸດຂອງຄຸນນະພາບແລະຄວາມຫນ້າເຊື່ອຖື.

HSM ຜູ້ສະຫນອງແມ່ນແບບການເຂົ້າແຈກຕາມສັ້ງທີ່ອອກແບບສໍາລັບການໃຊ້ງານອຸດົມສາຄາ, ກາຍເປັນພິສູດກັບຄວາມຖືກຕ້ອງ, ຄວາມແຮງແຂງ, ແລະຄວາມສາມາດໃນການຜະລິດຫຼາຍ.

ແມ່ນ, ເຂົ້າແຈຂອງ HSM ອອກແບບສໍາລັບການເພີ່ມຂຶ້ນ, ສຶກສາການຜະລິດຫຼາຍຢ່າງຕໍ່ເນື່ອງໂດຍມີຄວາມສະຫຼຸບສະຫຼີບທີ່ເທົ່າທຽມກັນ.

HSM ການນຳໃຊ້ຄວາມປິດປົກຄວາມໄປສູງໃນທຸກຂັ້ນຂອງການອອກແບບ, ການເຮັດມູ້ລູ້, ແລະການສອບສວນເພື່ອແກ້ວັນຄວາມຖືກຕ້ອງຂອງເຂົ້າແຈແລະຄວາມຍາວຄວາມຊີວິດຂອງมັນ.

ແມ່ນ, HSM ຜູ້ສະຫນອງການສະຫນິດຕະເວັນທີ່ມີຄວາມຮູ້ເຂົ້າໃນທັງໝົດຂອງຊີວິດຂອງເຂົ້າແຈ, ທີ່ມີຈາກການອອກແບບຫາການສົ່ງສິນຄ້າ.

ເວລາທີ່ຕ້ອງການແມ່ນກັບຄວາມສັບສົນຂອງໂຄງການ. HSM ກັບຄວາມສັງຄະເນີຍທີ່ມີຄວາມສົມບູນສູງໃນການສະແດງເວລາ, ເນື່ອງຈາກການປິດປົກຄວາມສູງແລະຄວາມຖືກຕ້ອງ.

ແມ່ນ, HSM ຄຸມກັບລູກຄ້າ B2B ເພື່ອສ້າງແມ່ແຍງຈາກເພື່ອນຂະໜາດແລະຄວາມຕ້ອງການຜົນิต.