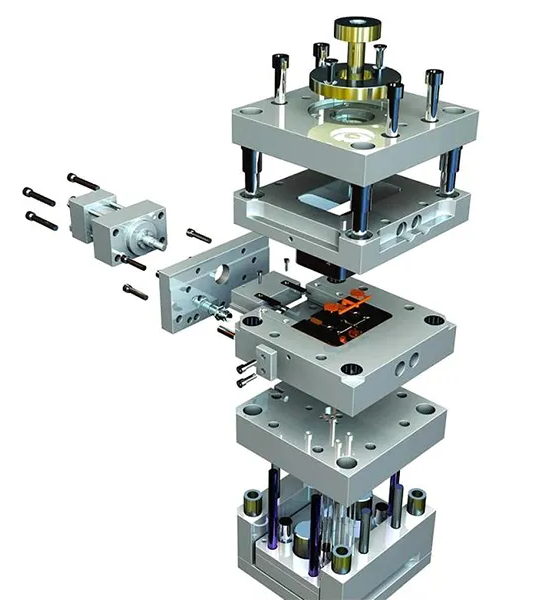

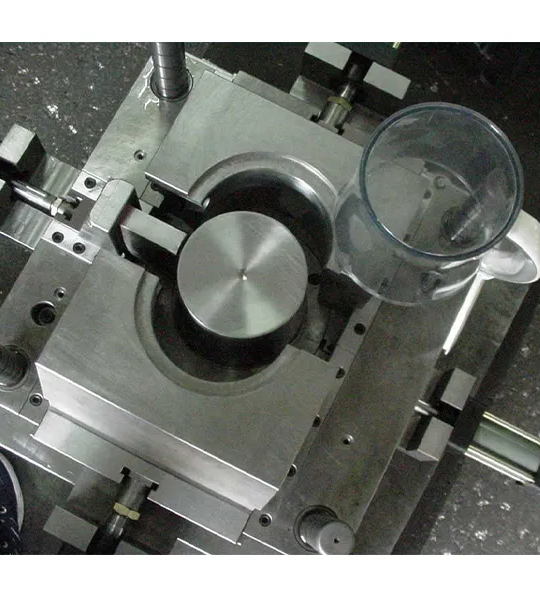

Гэр бүлийн молд: Хамгийн сайн гэр бүлийн бүтээгдэхүүнүүдийг хөгжүүлэх тухайн дизайнууд

Гэр бүлийн машин зурах төрөл нь эрхэм гэр бүлийн машинуудыг үйлдэх, хэрэглэгчийн шаардлага хангалттайгаар тодорхойлогдоогүй дизайнуудыг олгодог. Түүний хурдан өөрчлөлтийн чадвар нь алдахгүй, ашигтай байдлаар ихэнх машинуудыг үйлдвэрлэх боломжийг олгодог. Хамгийн их үйлдвэрлэгчид нь өргөтгөсөн зурах төрөл бүрийг ашиглан өөртөө ялгаруулж, суурин, энергийн ашиглалтыг багасгах, үеэрээ хугацаанд үлдэгдэлтэй байдлыг нэмэгдүүлэх функцуудыг олгодог. Гэр бүлийн машин зурах төрөл нь тодорхой мөн чанарыг хадгалах, хэрэглэгчийн амьдралыг сайжруулах, хямдрын бүтээгдэхүүн болохыг зөвшөөрдөг.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ