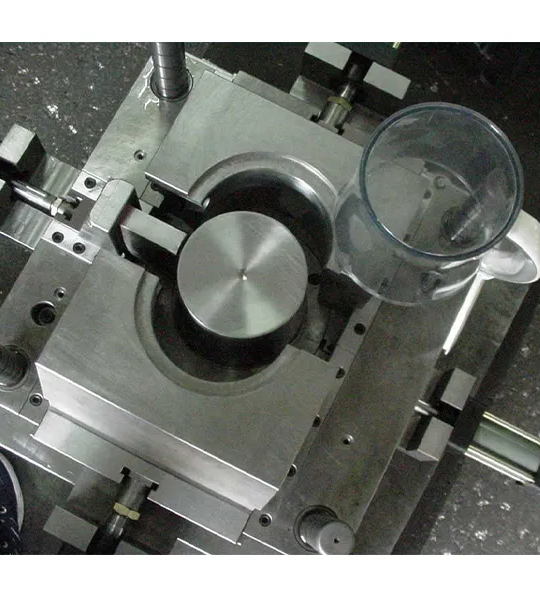

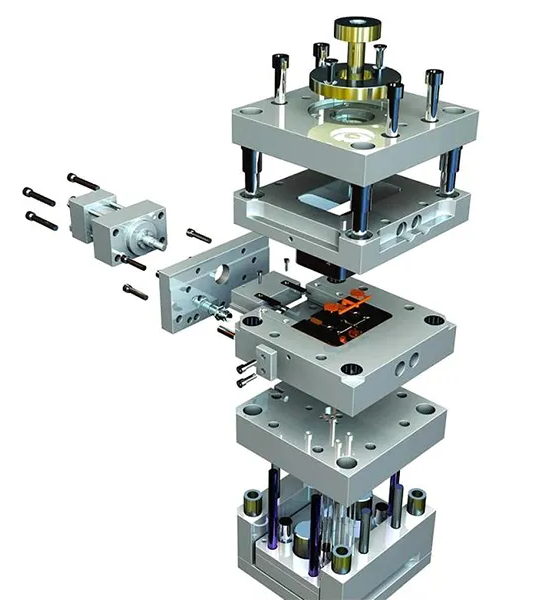

Cov Khoom Siv Hauv Tsev Pwm: Tsim cov qauv tsim tshwj xeeb rau cov khoom siv hauv tsev

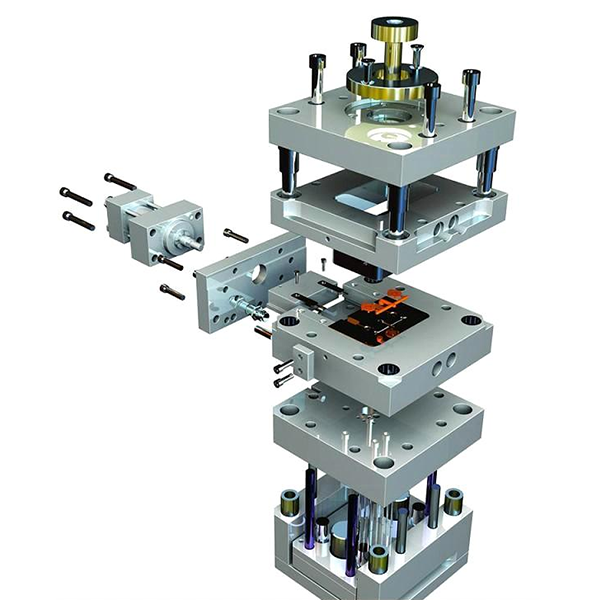

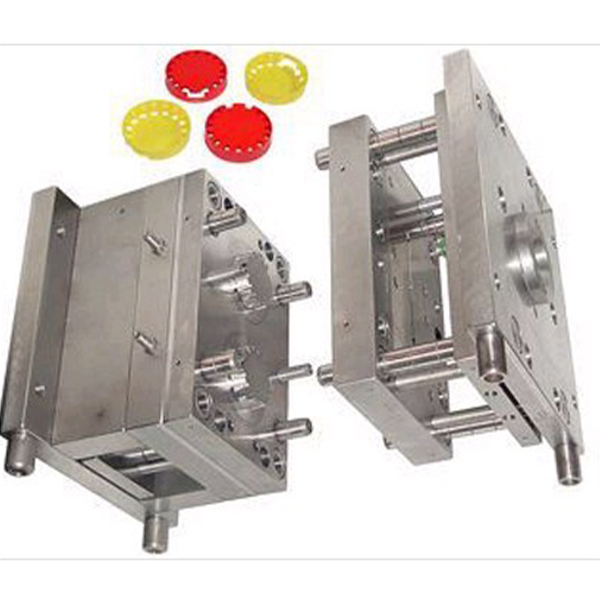

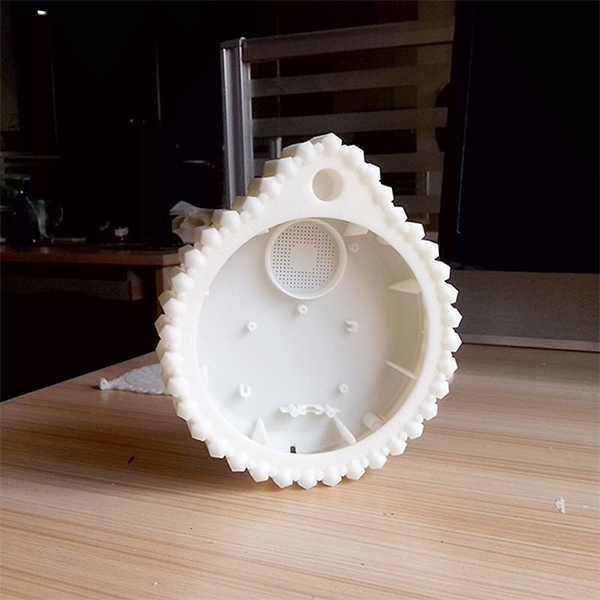

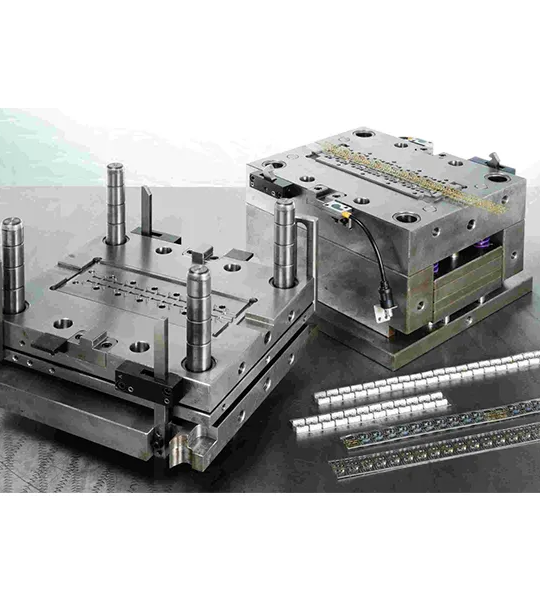

Cov khoom siv hauv tsev pwm muab cov qauv tsim los tsim cov khoom siv hauv tsev tshwj xeeb uas ua tau raws li cov neeg siv khoom xav tau. Nws versatility tso cai rau kev tsim khoom ntawm ntau yam khoom siv, los ntawm cov tub yees mus rau lub tshuab ntxhua khaub ncaws, nrog rau kev ua tau zoo thiab kev ua haujlwm zoo. Nrog rau kev tsim pwm tsim, cov tuam ntxhab tuaj yeem tsim kho tshiab thiab sib txawv ntawm lawv cov khoom, muab cov yam ntxwv uas txhim kho kev yooj yim, kev siv zog, thiab kav ntev. Cov khoom siv hauv tsev pwm ua kom zoo ib yam, ua kom muaj kev tsim cov khoom siv uas txhim kho lub neej ntawm cov neeg siv khoom thiab sawv tawm hauv kev sib tw ua lag luam.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ