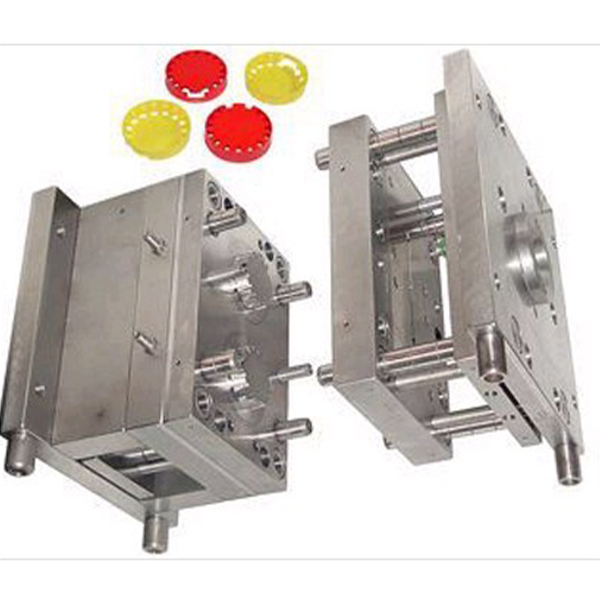

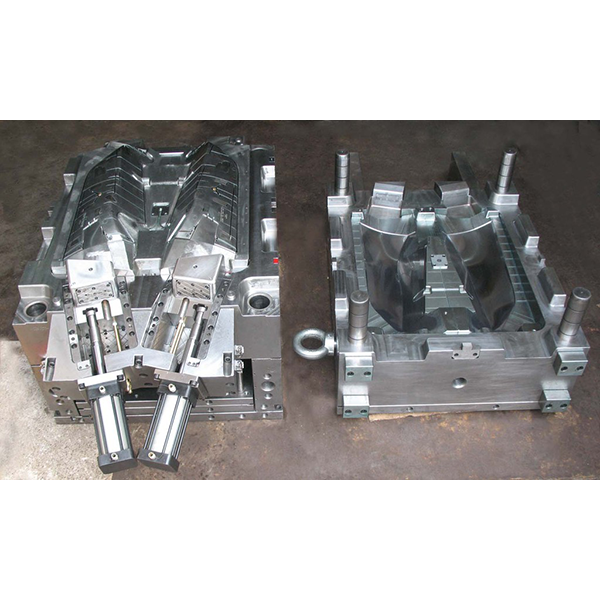

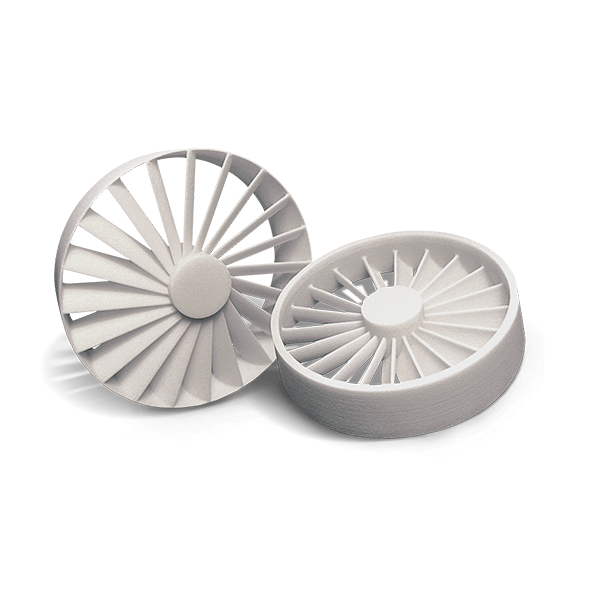

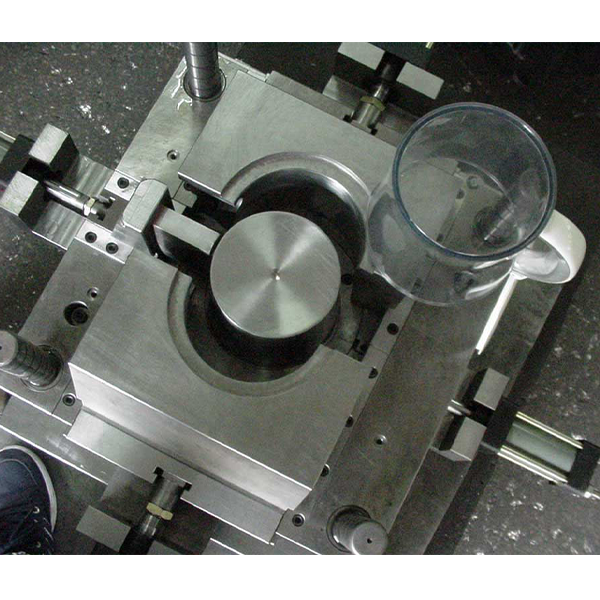

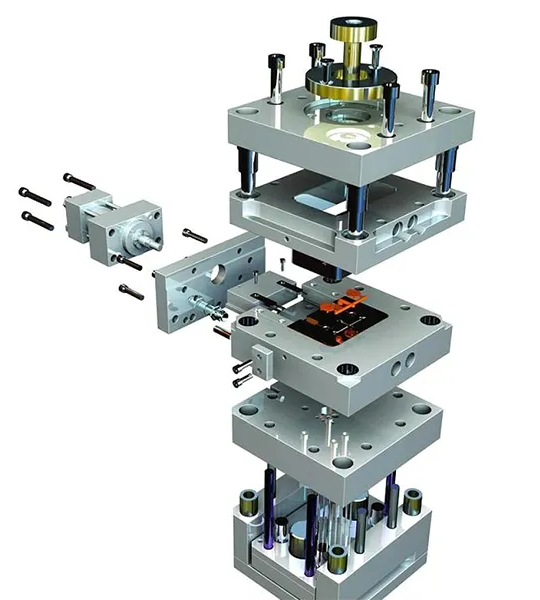

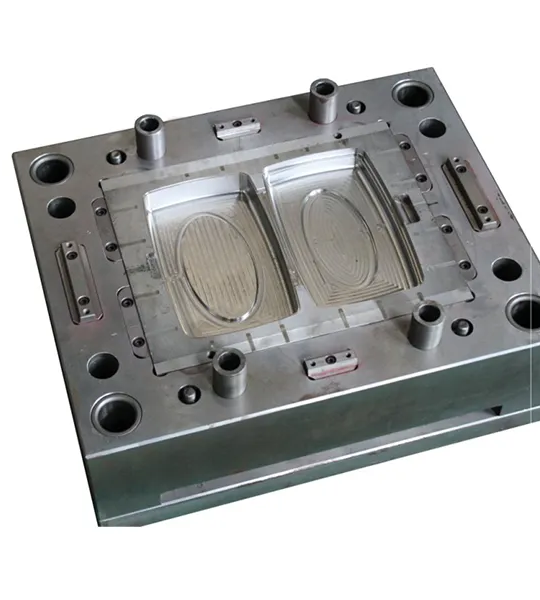

গিয়ার মোড: অটুট গিয়ার উৎপাদনের জন্য দক্ষতাপূর্ণ প্রকৌশল

গিয়ার মোড অনুপম দক্ষতা প্রদান করে, যা ক্ষতির সর্বনিম্ন পরিমাণে অটুট গিয়ার উৎপাদন নিশ্চিত করে। এর উন্নত ডিজাইন এবং উৎপাদন প্রক্রিয়া গিয়ারের জন্য প্রয়োজনীয় ঠিকঠাক বিন্যাস গ্যারান্টি করে, যা বিভিন্ন অ্যাপ্লিকেশনে দক্ষতা এবং পারফরম্যান্স বাড়িয়ে তোলে। গাড়ি থেকে শিল্প খন্ড পর্যন্ত, গিয়ার মোড উচ্চ গুণবত্তার গিয়ার উৎপাদনে সহায়তা করে যা সুচারুভাবে এবং নির্ভরযোগ্যভাবে চালানো হয়, সবচেয়ে কঠোর পরিবেশের দাবিও মেটায়। সঠিক দন্ত প্রোফাইল এবং দৃঢ় নির্মাণের সাথে, গিয়ার মোড গিয়ার তৈরি করতে সাহায্য করে যা শক্তি সংক্রমণে উত্তম কার্যকারিতা এবং দীর্ঘ জীবন প্রদান করে।

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ