- الصفحة الرئيسية

-

منتجات

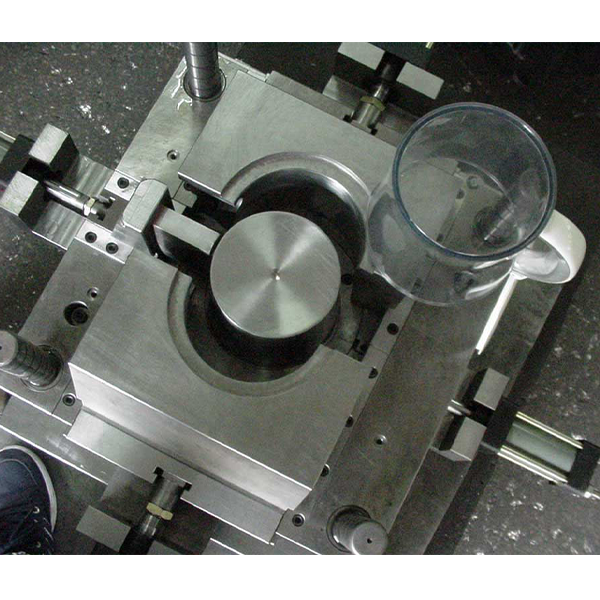

- تصميم قوالب بلاستيكية ODM/OEM

- مكونات قالب بلاستيكي

- تشكيل بالحقن مع التغليف فوق السطح

- قالب تروس

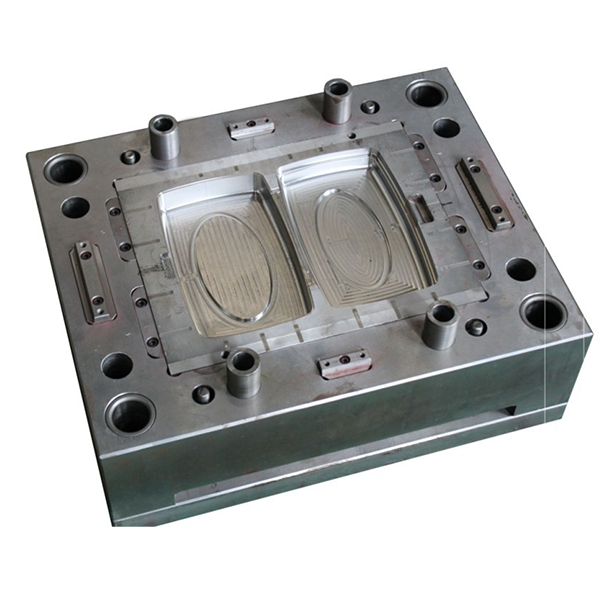

- قوالب الأجهزة المنزلية

- قالب الفك

- قالب البلاستيك عالي الحرارة

- تشكيل بالحقن الإلكتروني

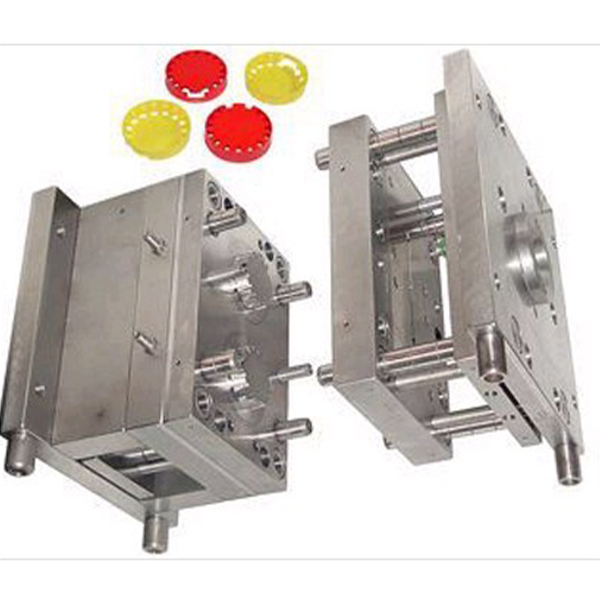

- تشكيل بالحقن متعدد الكهوف

- تشكيل بالحقن الطبي

- التشكيل بالحقن المزدوج

- قالب حقن السيارات

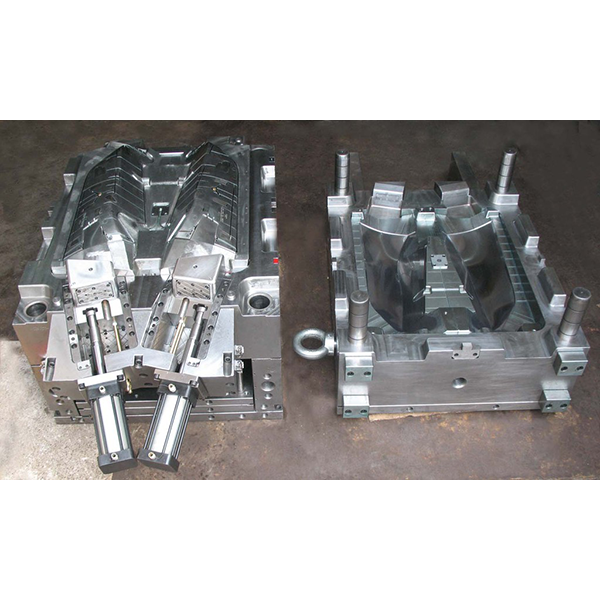

- قالب أجزاء السيارات البلاستيكية

- قوالب أجزاء السيارة

- قالب الحاقن

- معلومات عنا

- الخدمات

- أخبار

- حالة

- اتصل بنا

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

SL

SL

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

BN

BN

HMN

HMN

LO

LO

LA

LA

MI

MI

MN

MN

NE

NE

MY

MY

UZ

UZ